Ineffective MRO processes carry significant risks, which include among others, Unplanned equipment downtime.

A recent conversation with a very very senior supply chain leader who was the head of Supply Chain at one of the world’s largest FMCG organisations, had changed roles and taken on a position in a heavy asset / engineering environment with MRO parts.

He mentioned that in his FMCG role he ran the S&OP process and had engagement at all levels of the industry, the process ran like clockwork. However in his new world, he can’t even get the attention of the executive, no one turns up no one is interested. he has gone from the crown prince to the ugly cousin!

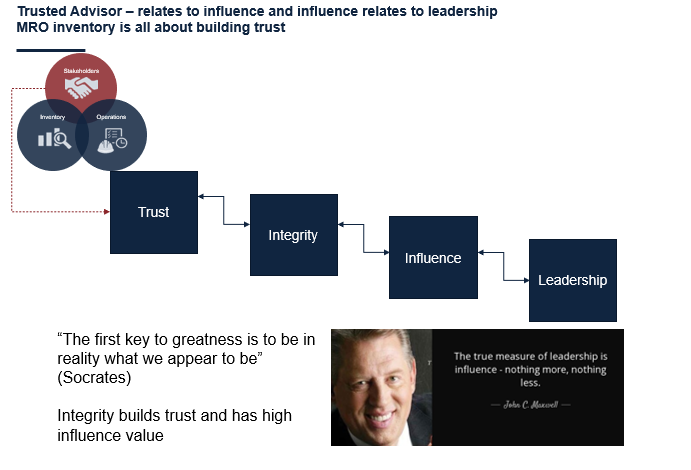

My response was simple – the MRO environment requires a stronger leadership position to drive results, where instead of the processes being culturally accepted, you must build respect and trust in the organisation. Hence the focus on both.

The key takeaway from this session – if you take only one thing, is simple –try to acknowledge the importance of soft skills – including leadership, change management and communications. Put down your inventory textbooks and algorithms and pick up leadership books and emphasise this need!

Introduction:

In this article, we define what MRO is and look at MRO activities against the overall operations and supply chain management functions that exist to run a business on a day-to-day basis.

Current Market and Landscape: Dramatic shift in the drivers of supply and demand and the knock-on impact it has on organisations pressures and conditions in which we operate.

Governing Thought: What we should be focusing on, and why managing and succeeding in an MRO inventory environment is not just about inventory!

Key Pillars to focus on so you can execute a “what, why and how”

- Know your inventory “p’s make degree’s” or “4’s open doors”

- Know the operation “Genchi Genbutsu” (Toyota Production System, n.d.) go and see “understand the application”.

- Know your stakeholders “Add value, develop relationships and build trust”.

What is MRO?

Industrial MRO refers to the Maintenance, Repair and Operations of machinery, equipment and/or the set of operations and activities used in the production/manufacturing process, but not ultimately seen in the finished products themselves and/or associated with the upkeep of a plant or facility which can include the physical maintenance of the structure or building, the systems that operate within the facility, and the equipment used to produce the plant or facility’s primary business output.

MRO concerns itself with the maintenance and repair of a plant or facility, which can be subdivided into several areas, that include(Thomasnet):

- Infrastructure repair and maintenance

- Production equipment repair and maintenance

- Material handling equipment maintenance

- Tooling and consumables

The meaning of MRO in supply chain and procurement

In some cases, companies have a hard time distinguishing between MRO inventory and production items.

MRO items are those that contribute to the end product or service but are not part of the final product. They do not generate profit directly but are an essential expenditure that ensures production continuity/service delivery. As such, MRO costs will show on your accounting sheets under indirect spend.

Market Conditions and Landscape

- Alternate approaches to maintenance, delaying changing to high level of break down / run to fail.

- Changing organisation structures, centralised, decentralised.

- Business Improvement, cost reduction, re-alignment.

- Highly pressurized environment, cost cutting fatigue.

- Call out that we did see an elevation in supply as a function to assist in the cost driving mandate. “We are working with you” Russel Hodson Rio Tinto .

- Huge loss of capability in the industry in the middle management level. Grey hair removed, knowledge lost.

- With the recent upswing, market has quickly absorbed excess capacity – large emphasis on debottlenecking with waves of sustaining capital and new growth projects .

- CSG organisation looking to maximise the production capacity from wells.

- Big upswing, Suppliers have optimised and centralised inventory holdings so lead times and performance have shifted as demand wasn’t anticipated.

- Perfect storm for inventory to play a role to support.

Governing Thought

Typically, we have two types of people who manage inventory:

- Inventory People: Inventory Professionals “inventory nerds” who think the world lives and dies on algorithms, systems and master data management

- Non Inventory: Contracts and Procurement, legal accounting and finance

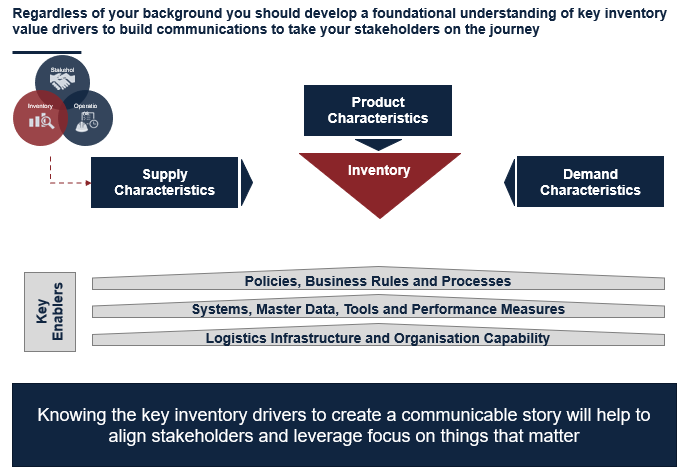

Regardless of your background and view of the world Inventory in an MRO operations are not about inventory, inventory is a means to an end to support the operation in delivering asset availability.

Let’s not get confused on this, inventory management is a support function with the purpose to give availability at the least cost and the most optimal risk position.

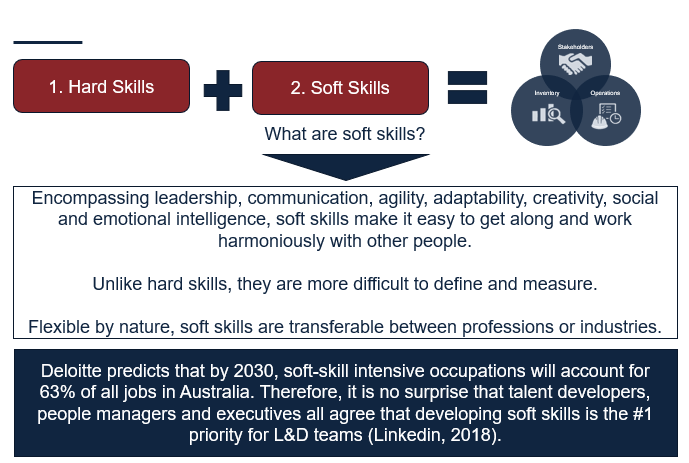

With the market context and landscape, we must not only be competent at the hard skills in MRO inventory, but need to acknowledge the leadership role required to truly excel;

- To ensure enough hard skills to drive functional outcomes from the team “p’s make degrees”

- Acknowledge the importance and develop the emphasis of soft skills to build trust, add value and be an integral part of how the performance of the organisation.

- Develop an overarching “why” that can deliver the “what’ and execute the “how” by focusing on:

- Know your inventory: “p’s make degree’s” or “4’s open doors”

- Know the operation: “Genchi Genbutsu”, go and see, “get your hands dirty, understand the application”

- Know your stakeholders: “Add value, develop relationships and build trust”

Stop worrying about why you think you should demand a seat at the table but focus on adding value and building trust and delivering so that you will be so integral you are asked.

Key Pillars of Focus:

- Know your inventory

- Know your operation

- Know your stakeholders

What are Soft Skills?

Encompassing leadership, communication, agility, adaptability, creativity, social and emotional intelligence, soft skills make it easy to get along and work harmoniously with other people.

Unlike hard skills, they are more difficult to define and measure.

Flexible by nature, soft skills are transferable between professions or industries.

Pillar 1 – Know your Inventory:

Inventory Foundations

Due to knowledge loss, change in focus or change in organisation, there seems to be a misaligned view of the inventory foundations and a lack of foundational inventory management fundamentals:

“P’s make degrees” , “fours open doors”

Drivers of Inventory

Importance of segmentation

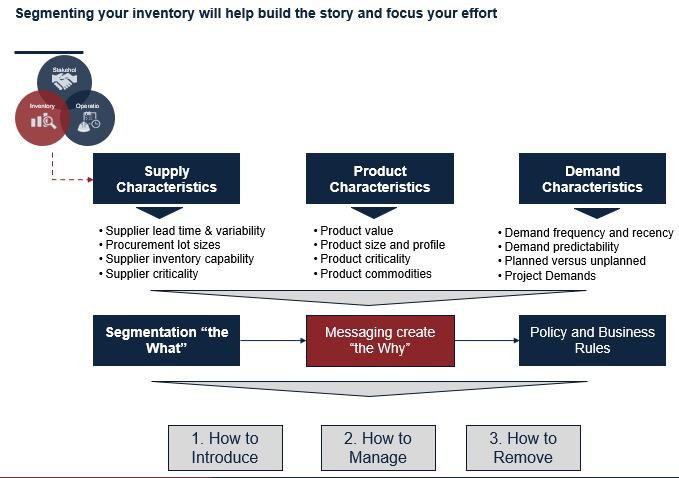

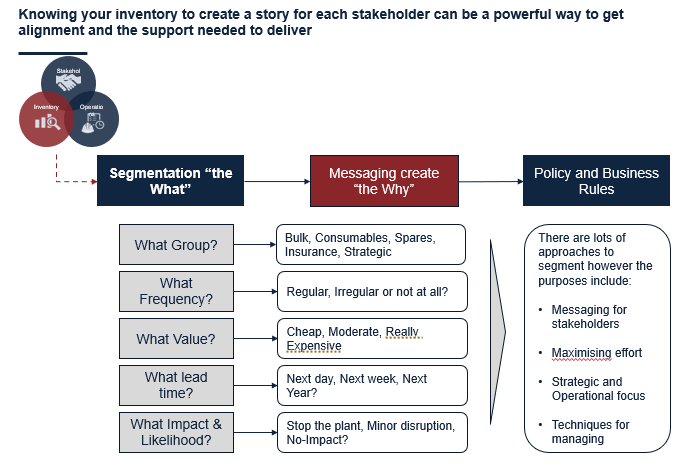

Segmenting your inventory will help build the story and focus your effort if you cannot quickly summarise your inventory for your stakeholders in terms of what you have in what categories’ you could be fighting an uphill battle.

- “finance” your stock turns are less than 1? Well you can see we have X million on hand that has not moved in 4 years and half of it is classified as strategic and insurance spares so we have a plan to work on this with operations and maintenance”

- Also gives an easy approach to focus your energy and application of how inventory segments will be managed and “why”, 70,000 materials with a team of planners “how on earth to we get our of the churn” lets focus on:

- What drives service and delivery performance

- What drives cost or high cost

- What will expose us to risk?

- Lets automate or “ignore the rest” diminishing returns (controversial I know but we only have so many hours in the day” we do this strategically though rather than trying to cover all?

- Supply – lead times, with the changes in the…

- Demand – demand types and triggers

- What moves frequently, what moves infrequently and what doesn’t move much at all.

- Product – critical items, Strategic spares

Develop basic policy frameworks:

With MRO – Most of the inventory challenges we have today are due to poor process and approval for purchasing in the first instance.

- How we introduce: Are you sure you need to by 10,000 of these given there is stated lead time of 3 months and you are only planning to use 50 per quarter?

- How we manage: Focus your attention on energy both operationally on how you manage inventory and strategically in terms of where you should hold and the agreements you need to structure.

- How we remove: Ok so I get this is a critical item however we have a lead time of 2 weeks, you have 50 on hand and you haven’t used anything for 5 years? Can we do something to reduce this?

Pillar 2 – Know your Operations:

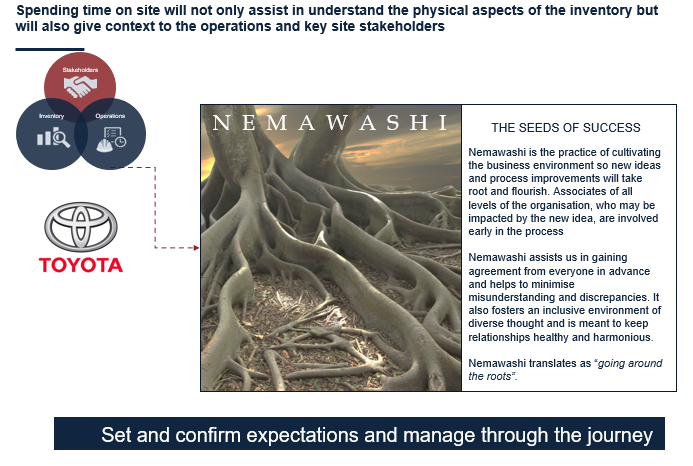

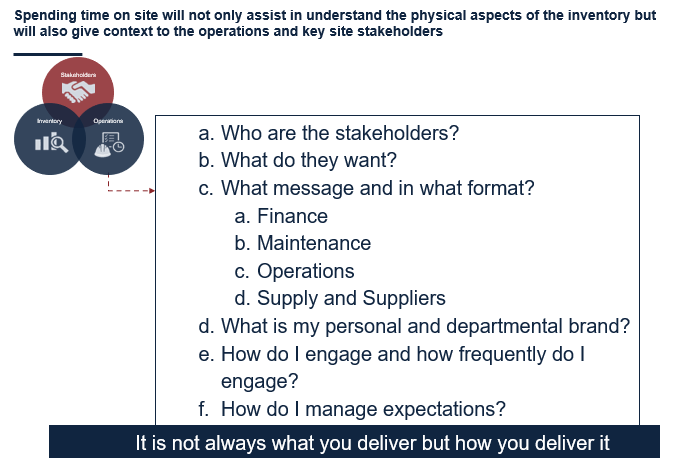

Nothing will build understand than going to site and working with stakeholders to get a real handle on inventory.

Pillar 3 -Know your stakeholders:

References

(n.d.). Retrieved from https://kanbanzone.com/resources/lean/toyota-production-system/genchi-genbutsu/

(n.d.). Retrieved from https://www.thomasnet.com/articles/plant-facility-equipment/what-is-mro/

(n.d.). Retrieved from https://limblecmms.com/blog/mro-maintenance-repair-and-operations/